Horizontal edge polishing machine with tilting polishing unit and milling function for protruding edges (box production).

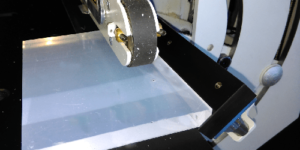

TILTING MILLING / POLISHING UNIT

The milling / polishing unit can be tilted downwards.

This makes it possible to create a chamfer with

constant size over the complete workpiece without

affecting the result because variations in

material thickness.

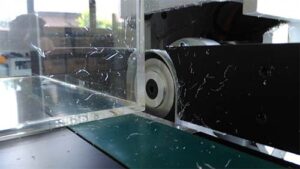

PROTRUDING EDGE MILLING FUNCTION

The machine makes it possible to mill

protruding edges to make boxes that are flush with

the surface of adjacent surfaces.

TOOL CHANGE

Tool change is quick and easy.

After the tool change, no adjustments to the machine are

necessary, so you can start production immediately.

MILLING / POLISHING TOOLS

A selection of more than 40 tools allows processing

of plastics (PMMA, PC, PET-G, SAN, etc.) or composite

materials (PMMA with aluminum or paper). As well as

the production of high gloss, shiny or satin finished surfaces.

With the tools of the type HIGH SPEED you can increase

the feed rate up to 200%.

TECHNICAL DATA

|

Thickness of piece at 0 ° (mm) |

2 … 35 |

|

Thickness of piece at 45 ° (mm) |

2 … 25 |

|

Workpiece length (mm) |

max. 500 mm |

|

Tilting range (°) |

3+° … -48° |

|

Milling spindle power (kW) |

0,55 |

|

Power of feed motor (kW) |

0,3 |

|

Machine length (mm) |

800 |

|

Machine width (mm) |

800 |

|

Machine height (mm) |

1.320 |

|

Work table height (mm) |

960 |

|

Weight (kg) |

170 |

|

Feed speed (m/min) |

0,1 … 5,0 |

|

Cutting speed (rpm) |

0 … 18.000 |

|

Milling depth (mm) |

0,05 … 1,5 |

|

Milling depth at 45 ° (mm) |

0,05 … 5,0 (per step) |

|

Voltage / Frequency (V / Hz) |

230 V 50 Hz (options available) |

|

Vacuum cleaner interface diameter (mm) |

38 |

|

Total power (kW) |

1,0 |

|

Included tool |

High gloss – code BLUE |